More construction details

- Shark-nose (SN) on the leading edge takes care of better aerodynamics of this part of the canopy, as well as higher inner pressure at wide range of the attack angles (meaning airspeed).

- The leading edge is stiffened with synthetic rods of the FET (Flexi Edge Technology), distinctly improving launch quality and guarding against collapses at high speeds.

- The design features also other effective methods of canopy loads distribution, mediated by most modern sewing technologies.

- Four rows of suspension lines are joined at the risers, equipped with compact yet very efficient tools like trimmers, speed and Power Attack (PA) system.

- Steering system of the DriftAir is our well known, original solution of 2D steering, this time with new TCT+ handle (Triple Comfort Toggle), combining features of both the TCT and TST (Tip Steering Toggle).

- As per our standard, the risers are equipped with three optional positions for the steering pulleys and magnets to choose from. Thanks to all these features, steering operation is straightforward and intuitive.

- Obviously, in some powerpack/canopy configurations considerable amount of torque can appear. To counter this, there is proven in our Warp an automatic TEA system (Torque Effect Adjuster). It works on its own after placing the line on proper side, depending on the torque direction.

- The canopy has the SL rigging (Sheathed Lines – meaning most of the lines are sheathed, with only some at the canopy unsheathed). The colours are assigned according to PMA standards.

DriftAir is manufactured entirely in Europe, at our Polish plant, so that we have total control over its sophisticated production process (using among else the advanced LT (Laser Technology) cutting.

Design solutions, technologies and other functionalities are listed below in the Technologies section.

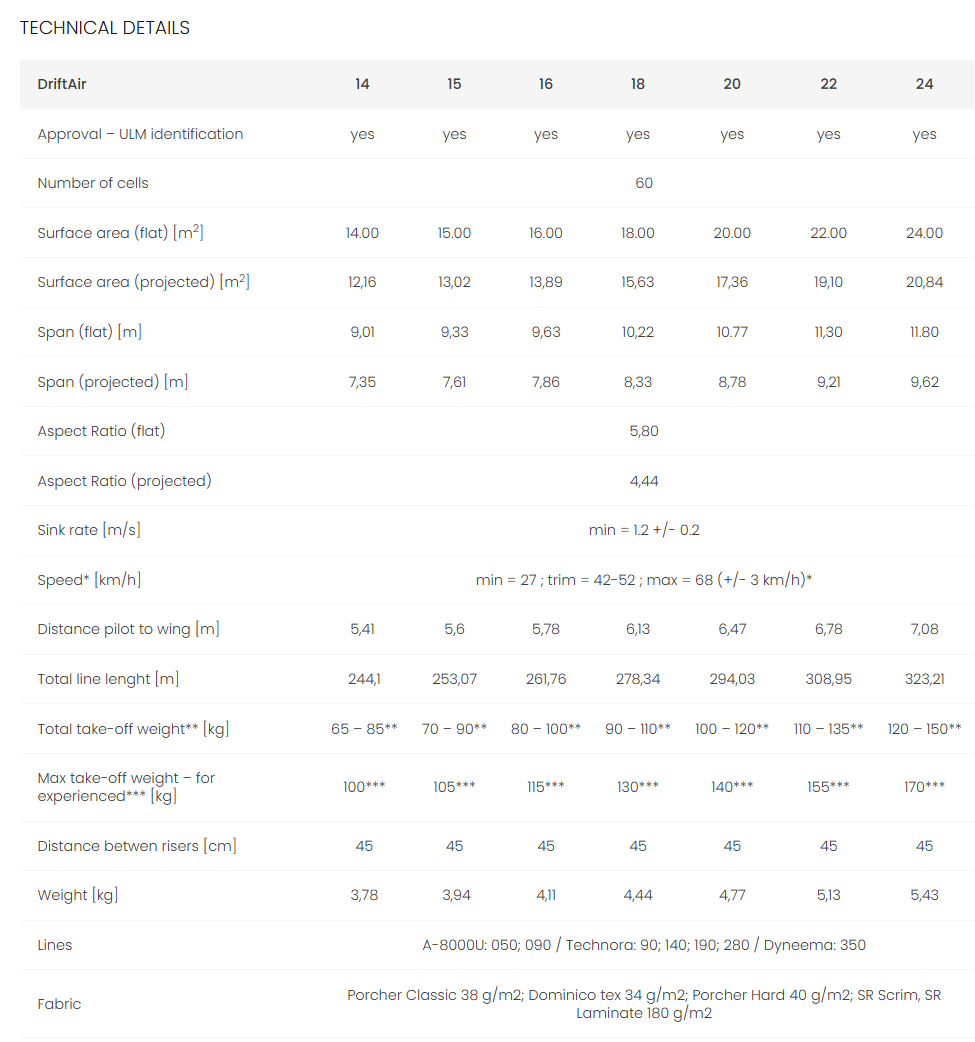

Parameters

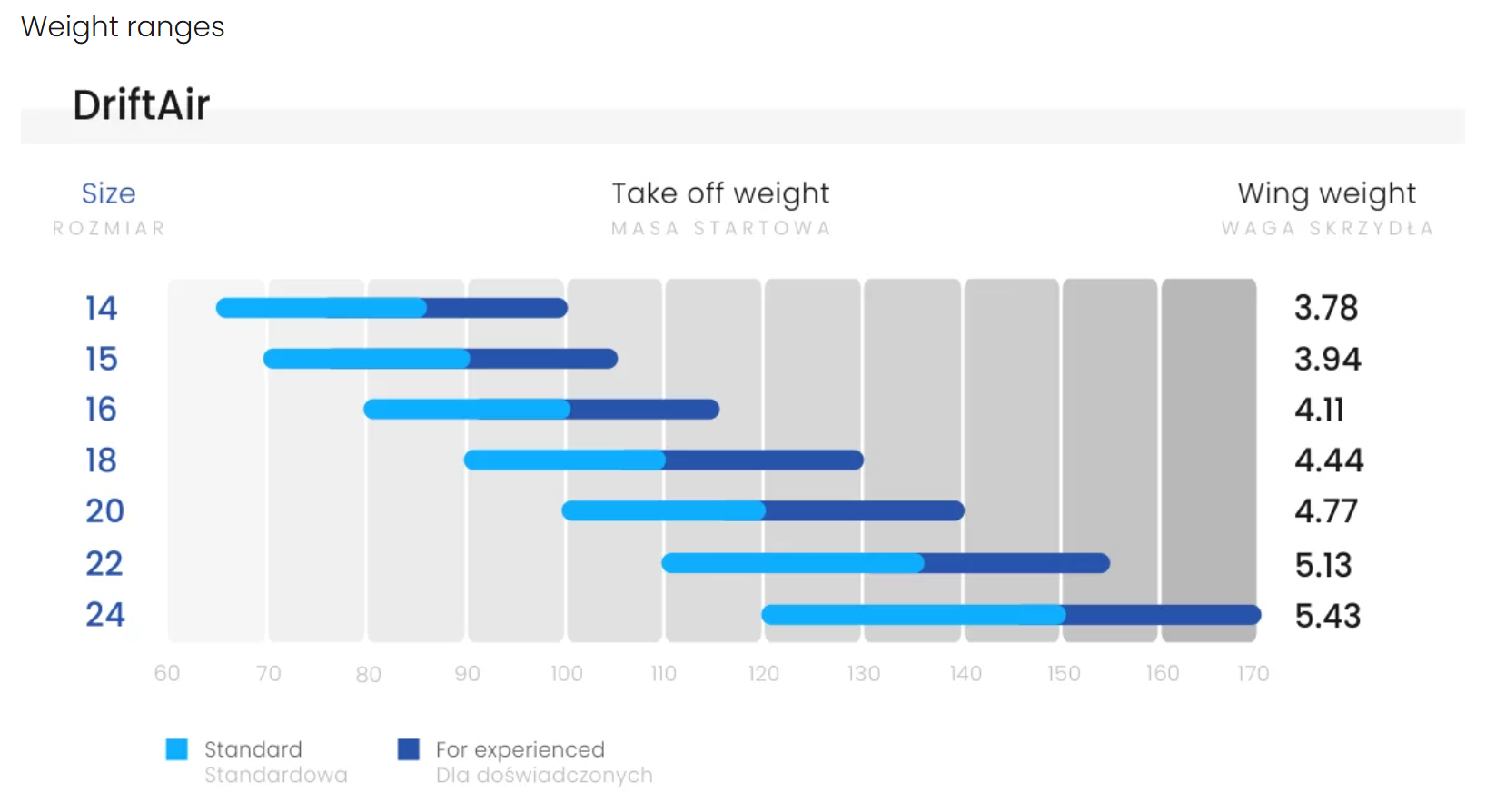

* Speeds are given as estimated for the middle wing size and the middle of its weight range. These speeds can vary within +/- 3 km / h depending on the size, take-off weight and additional factors such as air pressure and temperature.

** The basic rule is to choose the size of the wing so that the take-off weight is in the middle of the weight range. Less weight on the wing (lower range take-off weight) can be considered for foot take-off, when flying in calmer conditions, or when we want to improve economy. More experienced pilots who want to fly dynamically, have higher speed and fly in more demanding wind conditions can consider greater wing loading (take-off weight in the upper range). This is a common option among trike users.

*** Note – the canopy significantly changes its behavior with increasing wing loading. The greater the loads, the greater skill and concentration of the pilot are required.

Colours